A Lean organization is driven by its standards. Standard Operating Procedures are used for production staff, to describe was needs to be done and how to do it. For supporting functions and managers, defining standard work can be more challenging, especially since their work cannot be planned 100%.

What can be captured in the Leader Standard Work or Standard Work for Supporting Functions are activities like daily accountability meetings, Kamishibai & Gemba walks and activities or reports that need to be handed in regularly.The second challenge of Leader standard Work is not to focus only on if the task or job was done, but also on what behavior the person has shown during these activities and meetings.

In the remainder of this article I will write about Leader Standard Work, since this term is used in Lean literature. The principles however can also be used for indirect functions who are not managers.

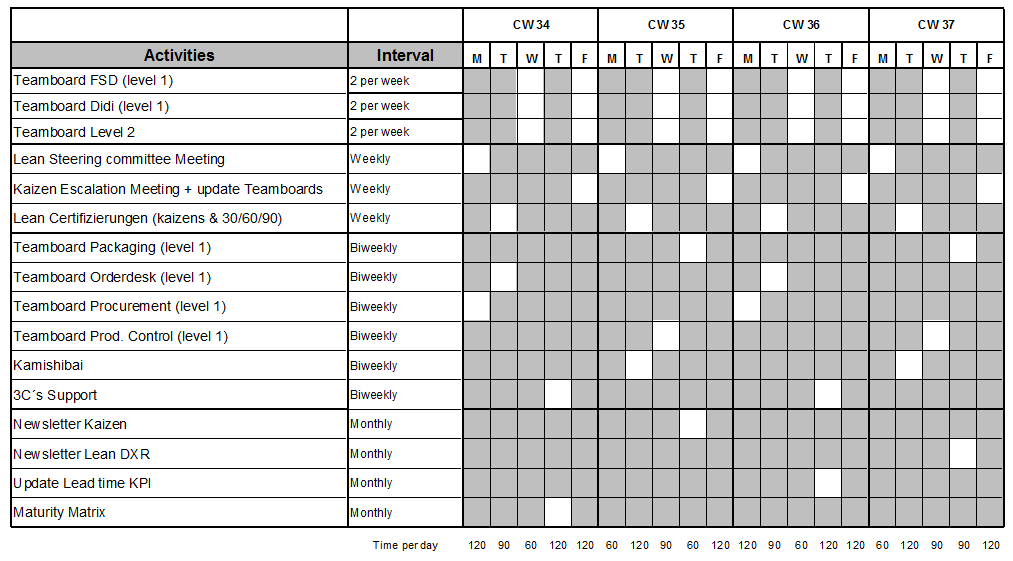

The first challenge of LEADER STANDARD WORK is defining the what-part. What tasks does the person put on his Standard work sheet? I illustration 1 shows an example: my personal leader Standard Work,

Activities can be planned for different intervals, in this example daily to monthly, since one A4 consist all standard activities for a month. As can be seen at the bottom, my standard work takes about 20% of my weekly available time.

Using white cells as the ´color´ to show that something should be done, makes it easy to visualize at a later stage of something is done or not using color-coding. If the task is completed, make it green, if not, make it red.

Illustration 1: Leader Standard Work Example: the WHAT part.

A few types of activities that can be captured with this type of standard work will now be described, starting with the responsibilities a person has in the MANAGEMENT AND ACCOUNTABILITY SYSTEM.

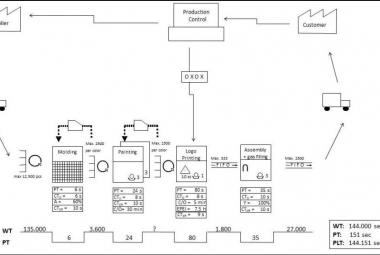

A lean organization typically has a fixed Meetings Structure in which team performance is discussed and problems can flow to the supportive functions and management in a matter of hours (Mann, 2005). These meetings can be both disciplinary and interdisciplinary, depending on the daily business, and people can take part in multiple meetings. In Lean organizations, these meetings are usually Stand-up meetings, in which a Communication cell is used.

Note: Due to my role as Lean facilitator who helps implementing the daily management system, there are a lot of team board meetings mentioned in my standard work (illustration 1).

A second topic I like to see in Leader Standard Work is GEMBA WALKS & KAMISHIBAI.

With Gemba Walks is meant, that managers come out of their offices and visit the shop floor to learn about the processes and problems that occur there (Mann, 2005). At the same time, visiting the Gemba gives the manager the opportunity to ask coaching questions and promote continuous improvement (Rother, 2010).

Next to asking coaching questions, the manager can perform a Kamishibai check, a mini-audit in which the sustainability of a random standard can be checked.

OTHER ACTIVITIES that can be added to the standard work can contain everything that is important to the person which need to be done regularly, which in my personal example includes communication activities and updating lagging KPI´s.

The what-part of Leader Standard Work which is covered until now, does not help you to review standard work, whether or not you have done a good job. It is therefore necessary to define HOW somebody is supposed to do act to be able to review (Daniels, 2000) performance.

Since Jeffrey Liker wrote the Toyota way in 2004, more and more people learn that Lean is about BEHAVIOR. When we would like to review whether or not a Leader has done a good job in the meetings they attend, we therefore need to define what these behaviors are (Webers, 2010).

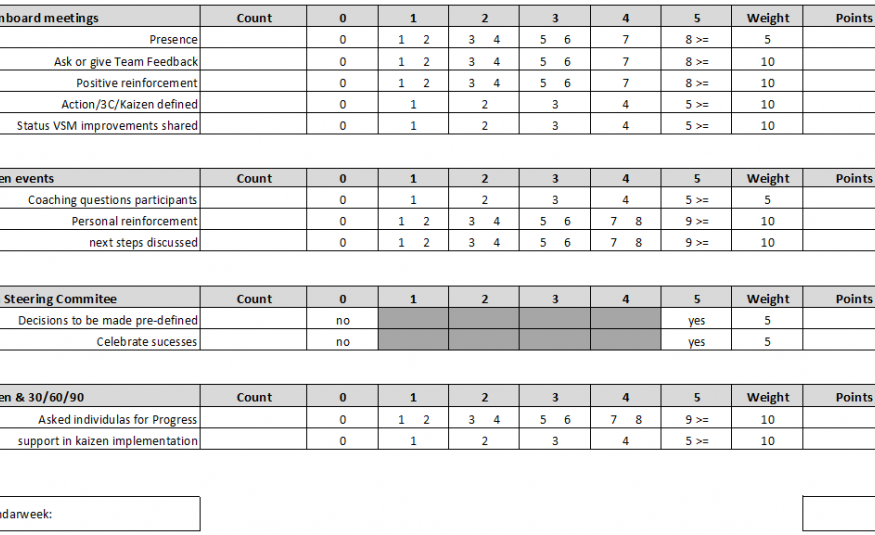

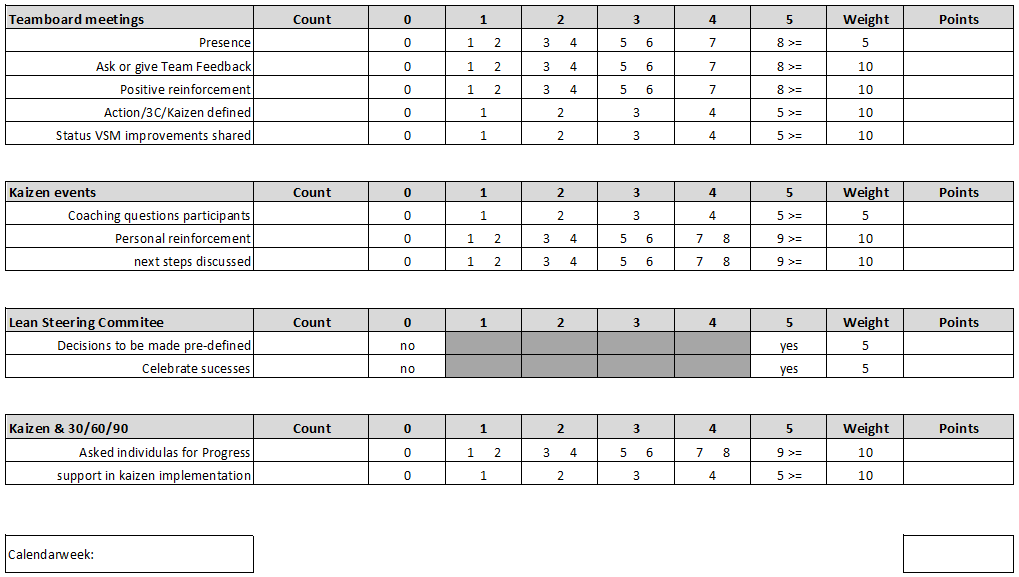

Illustration 2 below shows an example of my personal Leaders Standard Work. It shows the behaviors I need to show to facilitate a cultural change, by asking questions about suggestions for improvement (kaizen) and positively reinforce someone when they have done a great job.

One example that elaborates the need for a behavioral based Standard work as shown in illustration 2 is as follows: I can visit all Teamboard meetings as planned (10 a week) and not say a word. In illustration 1, I would be green on the entire sheet even though I might not have added any value to the meetings.

Illustration 2 mentions behaviors for me to show during the Teamboard meetings. How often did I give feedback about the Meeting efficiency? How often did I share information about the running Kaizen events with a team? And how many times did I compliment someone on their behavior in the meeting? Those are behaviors that tell me if I did my job right. If I stay silent at the meetings.

The trick about these behaviors is that they should be 100% amendable by the individual. At the end of the week, it can be discussed how the job was done. It would make sense of course, to discuss the behaviors with the team and manager of the individual, to make sure all are aligned on what ´doing a good job´ means for that individual.

The next step in being able to review the Leader Standard Work is to add a SCALE AND WEIGH-FACTOR to each behavior, which makes it possible to quantify behavior and prioritize on certain activities or behaviors.

In My personal example in illustration 2, the total amount of points I can earn in one week is 500. Counting how often I´ve shown certain behavior will give me 1-5 points, which will then be multiplied by the weight factor. Attending at least 8 in a week commcells will give me the maximum of 5 points for this behavior; the weight factor 5 will multiply these points to 25.

When I also give feedback about the efficiency of the meeting in all 8 of them, I can earn another 5 x 10 is 50 points. (Note: the factor here is twice as high as the meeting attendance).

As with all Lean Tools, the goal of the tool is to continuously improve performance. Thinking about what behavior you should be showing and reflecting on whether or not you have shown this behavior already helps you improve your personal effectiveness.

Illustration 2: Leader Standard Work Example: the HOW part.

Standard work is one of the most important parts of Lean. Only when is predetermined how a certain task should be done, it can be measured whether or not the job is done properly.

This article describes an example of how standard work can be defined for Managers and supporting functions. Just like standard Operating Procedures in production, these documents are living documents, which are continuously subject to changes to be able to maximize performance of each individual.

Continue to:

REFERENCES:

Daniels, A.C., 2000, Bringing out the Best in People - How to Apply the Astonishing Power of Positive Reinforcement, McGraw Hill

Liker, J., 2004, The Toyota Way, 14 management principles from the world greates manufacturer New York: Mc-Graw Hill (summary)

Mann, D.,2005, Creating a Lean Culture - Tools to sustain Lean Conversions, New York: Productivity Press. (summary)

Rother, M., 2010. Toyota Kata: Managing people for Improvement, Adaptiveness and Superior Results, New York: Mc-Graw Hill (summary)

Webers, N.C.W., 2010, Performance Behaviour – De Lean Methode voor het Continue Verbeteren van Prestatiegedrag, Den Haag (NL): Sdu uitgevers (summary)