Kaizen is the fourth and final part of my Lean House for the Shop-Floor (next to 6S, Standard Work and the Communication Cell). Kaizen is the Japanese term for Contiuous Improvement which should be performed by everyone, at all time, at all workstations (Imai, 1986). To facilitate continuous improvement, all communication cells should include a Kaizen-loop. Using this loop everyone can participate in the improvement process and improvements are communicated, structured and documented.

The following images who how we have implemented the Kaizen-loop in our factory (click on the images for a larger version):

The KAIZENLOOP [illustration 1] is present on all communication cells, in the form of a boxcontaining four sections for different statia of the Kaizen process: Empty forms (1), handed in Kaizen (2), Implemented Kaizen (3) and the Kaizen list for follow-up (4).The kaizen formshould be standardized and available for everyone to document their improvements.

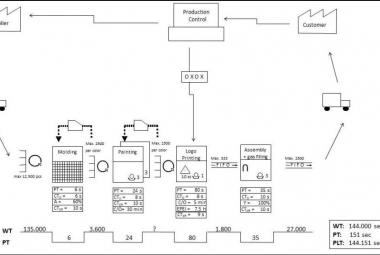

All kaizen should be focused on reducing at least one of the 8 WASTES [illustration 2]. When a reduction of the waste can be quantified, the kaizen can be implemented. Different types of waste can be found by using a processmap or by using any of the tools described in the article Finding Muda (waste) in your Process. Ideally, each department has a so called target condition, a concrete goal where the department can strive for (Rother, 2010). A target condition couldbe: reduce defects on line X with 1% each month.

Improvements can also result from the KAMISHIBAI rounds [illustration 3]. These mini-audits are used to check 6S standard and Standard Work weekly or even daily. Deviations from these standards can lead to either training of the standard, or an improvement of the standard and therefore Kaizen.

Finally, the number of Kaizens handed in and implemented should be monitored. I also believe in a certain form of TEAM REWARD SYSTEM in which small monetary rewards can be earned for each implemented Kaizen. The money saved can be used by the team at a quarterly external team activity. Secondly, the difference in kaizen performance per team visualizes possible coaching needs.

This is the last articlce in de series ‘Lean House for the Shopfloor’

Continue to the next series: