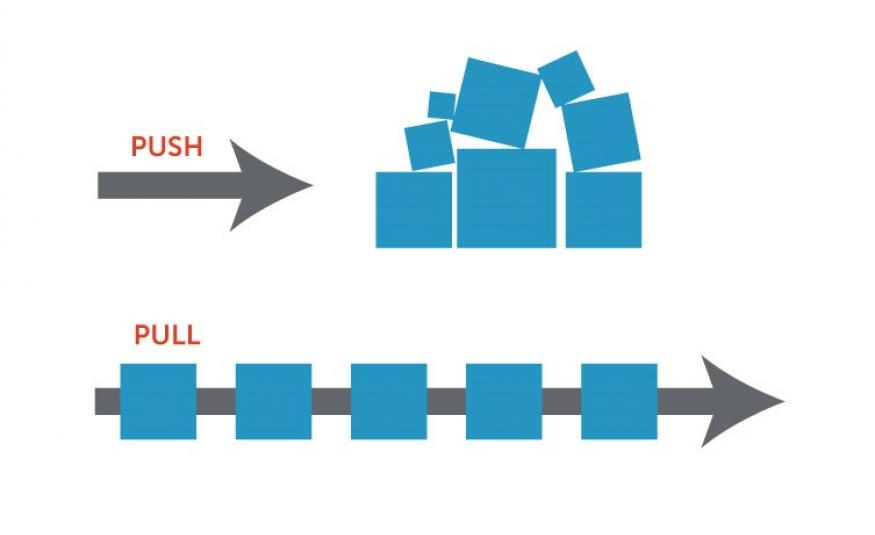

A Pull process is a process in which a workstation starts to work on his next order only when there is a free slot on the output side. This means the trigger for producing anything on the workstation comes from the customer side, which can be internal as well as external. The customer pulls orders through the process instead of a traditional Push connection in which products are produced no matter what happens on the output side of the workstation.

Because inventories between workstations are managed in a pull system, which directly influences and maximizes the Lead Time, Pull always has a preference over Push.

Three different forms of Pull connections can be identified: a Work cell with Continuous Flow, Sequential Pull and Replenishment Pull.

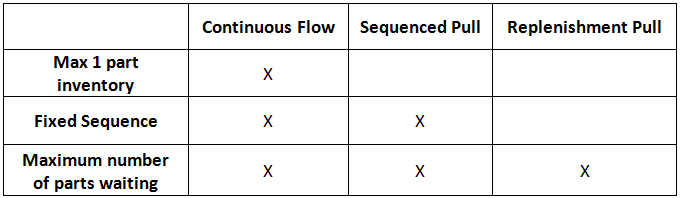

The THREE PULL CONNECTIONS help to achieve different levels of Pull in the system, based on three factors: having a maximum of one piece of inventory between two process steps (1), having a fixed production sequence (2), and having a maximum number of parts waiting (3).

The Continuous flow connection has the highest level of Pull, since all three factors are included. Products are worked on one by one and with a maximum inventory of one between the workstations, a workstation can only work one the product that is waiting in front of it at that time (the fixed sequence), and can only produce when the inventory behind it is less than one (no inventory). multiple workstations with continuous flow between them are also known as Work cells or U-cell.

The Sequential Pull connection is the second best possible Pull connection, in which the fixed quantity is determined, the sequence of product is defined, but a buffer with a defined maximum is allowed between workstations to buffer for variance. This is usually implemented using First-In-First-Out lanes (FIFO) .

Replenishment pull, the supermarket, is the third and last option, in which a maximum number of products is waiting to be worked on, but it is unknown which type of product will be pulled out next. This type of inventory is also known as a supermarket and can be controlled using Kanban.

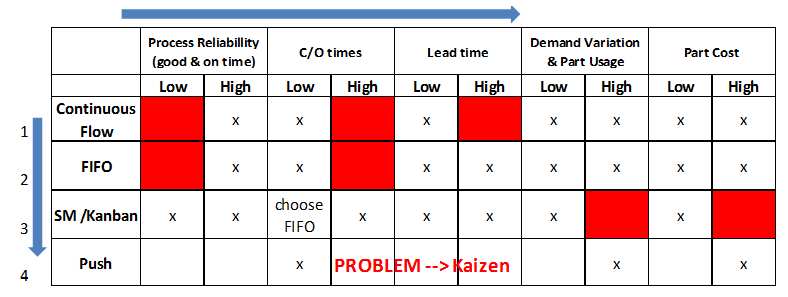

The differences between the three types of pull connections can be summarized in the following table:

Illustration 1: Difference between Continuous Flow, Sequenced Pull and Replenishment Pull

CHOSING THE RIGHT TYPE OF PULL CONNECTION is one of the steps in designing a Future State VSM. This decision depends on a few process- and product variables. Illustration 2 shows a discussion table with variables which might influence the decision for a type of connection. In the discussion it is advised to follow the topics from left to right, and move from top to bottom. The goal of the table is not to discourage the use of a certain Pull system, but to give direction in pointing out what variables need to be worked on to be able to implement a higher level of pull within a specific situation.

Illustration 2: Discussion table, when to use what type of connection?

Process reliability is the first factor that influences the type of Pull connection which can be used. When the reliability of the output of the upstream workstation is low, a buffer is needed to prevent the entire flow from stopping. Since in this case all products need to be buffered, the sequence cannot be held anymore which results in the Supermarket being the only viable option at this point.

Change-Over-Time is the second variable. In situations where more than one product is produced within a family, short change-over-times are needed to produce in sequence and per order on a workstation. Whenever Change overs are high, it would make more sense to batch products, which means a buffer is needed in front of the workstation. This buffer would be a supermarket, because the products are sorted by type, and therefore sequence cannot be kept.

Lead times also influence the type of Pull connection can be used. Continuous Flow can only be kept if the upstream process can respond to downstream changes. When the Lead time is higher than the cycle time of the machine, a buffer is needed to prevent starvation. The same holds for Takt Time. Only when the upstream machines can deliver on all Takt times (which can vary, for instance with seasonal products), continuous flow can be implemented. When some Takt levels cannot be achieved upstream, a buffer is needed.

The fourth variable is variation in demand of products, which limits the options for a pull connection the other way around. The higher the demand variation or product mix is the less desirable a supermarket is, because the number of buffers and the number of products per buffer increase. This variation should be minimized using Heijunka.

This also holds for the price of the part or product, the fifth factor. The higher the part costs, the less desirable the Supermarket option becomes. This is a tough one, because it might be necessary to have a supermarket to keep the pull system running even though the costs are high.

The interesting thing about these five factors is that there are situations where an unstructured Push connection might be the only option left and having Push connections in a Future State Value Stream Map is really not desirable. In these situations where Push seems to be the only option, kaizen events need to be defined to change on or more of the above five factors to make it possible to implement on of the three Pull connections.

The table shown in illustration 2 is meant for the purpose of discussion only. It is not black and white and does not include all possible factors that might influence the choice of connection type. It is the task of the Team that develops the Future State Value Stream Map to decide what connection type is suitable for each specific situation.

Continue to: