In Lean Transformations, Thijs Panneman describes the crucial steps of different lean tools, so that they direcly lead to productivity improvements. How? By reducing mura, muri and muda. To explain how this works, the book is split into five different parts: the role of the lean transformation leader, understanding the lean philosophy, four steps of lean maturity, redesigning processes to improve flow and some lean tools that were described along the way in more detail. This article will shortly address each of these five parts.

If you plan to change your organization into a lean organization you need more than the understanding of a few technical tools. Part one, THE ROLE OF THE LEAN TRANSFORMATION LEADER, contains the first three chapters, in which Panneman describes what you should consider.

Chapter one describes how to lead change, based on the five levels of leadership theory from John Maxwell and Mary Lippett’s five elements of change. The leaders that need to be developed are leaders that grow other leaders, to create a multiplier effect on their own actions, and to make sure the line of succession can come from inside the company. The leaders are also responsible for putting the five elements of change in place: vision, commitment, resources, skills and plan.

Chapter two and three describe how these leaders should grow other leaders: through training (chapter 2) and coaching (chapter 3).

Nothing is more boring than a training which is fully determined by slides. In terms of training elements, Panneman proposes to have blocks of 20 minutes in which a topic is introduced, discussed and practiced with, of which slides (when at all) are only used a couple of minutes.

Since lean has to do with a cultural change and therefore behavior, coaching is needed to help the organization learn these new behaviors. It is the transformation leaders who are doing this coaching sessions during these daily walks at the shop-floor.

Part 2 continues with creating an UNDERSTANDING OF THE LEAN PHILOSOPHY and contains chapters four to six. It describes why people started to look at Toyota in the first place and what it is that they did, that make them the best auto manufacturing company in the world.

Chapter four describes that lean is about improving flow, because it is the only parameter that influences all corners of the iron triangle: quality, cost and reliability. By improving the flow, you directly influence the lead time of your process, meaning you will deliver to your customer faster than before, possibly creating a competitive advantage.

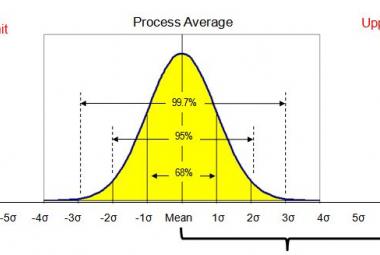

Chapter five described how flow can be improved: by reducing variation, overburden and waste (mura, muri and muda). These three words cover the three enemies of lean and are interrelated, meaning more variation leads to more waste, but also vice versa.

Chapter six explains how the lean philosophy can be described in terms of behavior, using the fourteen management principles that Jeff Liker described in 2004.

Part 3 includes chapter seven to ten and is the core of the book: THE FOUR LEVELS OF LEAN MATURITY, in which lean tools are described in such an order, that it will help you understand what they are, why they can be useful, and how they can help you improve your bottom-line results.

Chapter seven describes the first level of lean maturity: setting standards. It includes the tools 5S, Office 5S, standard work, and Leader Standard Work, which are necessary to implement in any company, just to keep the lines running at a predictable way. Without these standards, improvement is impossible.

Chapter eight describes the second level of maturity which is called checking the standards. This is where team boards and kamishibai audits are described as tools to help steer conversations in the organization about how we are performing in comparison to what we defined as the best practice.

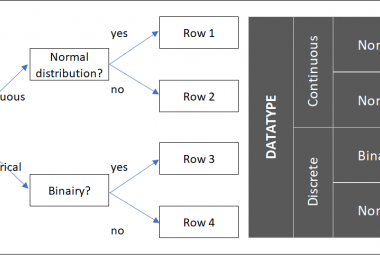

Chapter nine describes the third level of maturity and is called improving the standards. The whole goal of both the kamishibai audits and discussing performance at the team board meetings is to use the expertise of everybody in the organization to find and implement improvements. This chapter describes kaizen, A3 problem solving, and D2MAIC projects as possible ways of doing so.

Finally, the fourth level of lean maturity is about linking improvements to company goals is described in chapter 10. Meaning, that the best in class lean organizations do not just continuously improve their processes, they do so with a certain goal. They align all departments to the same direction: the number one KPI that is most important for the organization to achieve its vision. The daily management system and hoshin kanri are the tools described in this chapter.

There is however, more possible than using the above cultural changes. There is a strong lean tool available for REDESINING PROCESSES TO IMPROVE FLOW, called value stream mapping. This is the topic of part 4 and can be used at strategic level to determine where and what to improve first, to have the best impact on customer experience.

Chapter eleven to fifteen describe the different measures of time that are used in value stream mapping, the difference between push and pull and why pull is best, the most used symbols in value stream mapping using a lighter case, the eight steps of future state value stream mapping to help you determine which improvements will directly lead to measureable results, and value stream mapping in an office environment.

Finally, part 5 includes some LEAN TOOLS that can be used next to the many tools explained in the first 15 chapters. These include autonomous maintenance, kanban, SMED and a quick guide to clean up your email box, each with a dedicated chapter.

Lean transformations is a guide into the lean philosophy and how to use lean tools and principles to bring your organization forward. By describing the why what and how of every lean tool discussed in this book, you will be able to train better, improve more and get make sure everything you do gets measurable results. I encourage all that are interested in Lean transformations to read it immediately!

continue to:

sustainable 5S - T.Panneman (summary)

Source:

Panneman, T, 2017, Lean Transformations - when and how to climb the four steps of Lean maturity, Maarssen (NL): panview (order this book)