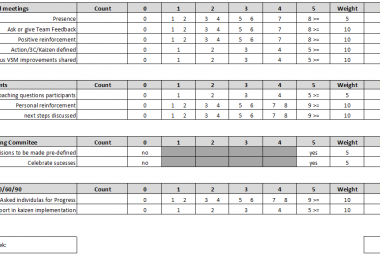

This week, I spent a lot of energy on our factory wide KPI break down (or in Lean terms: Hoshin Kanri). This breakdown is important to create focus in all activities in the plant (every action directly contributes to organizational goals) and to improve ownership at the shop-floor (“I can’t find the button OEE…”; “how do I know whether I made the right call when I intervened in the process?”)

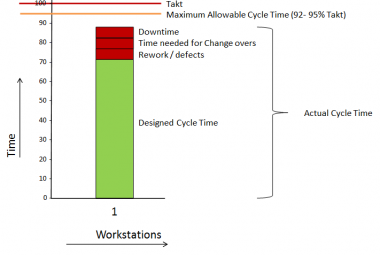

In a series of workshops we are developing a blueprint of the KPI breakdown which cascades Key Performance Indicators (KPI) at management level into Behavioral Indicators (BI) at shop floor level. With the Lean team, we defined three questions which will help us determine what the BI at a workstation will be:

- What KPI can the operator influence?

- When is the operator supposed to intervene in the process?

- How can the decisions to intervene be visualized so that these decisions can be monitored on a hourly basis?

In the coming weeks, we will design the complete break-down together with colleagues from all levels and departments.

Continue to: