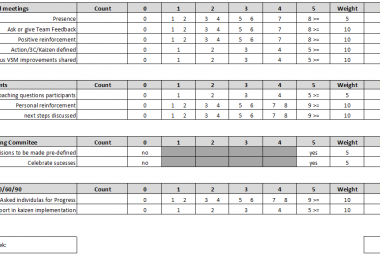

This week the operators from the Autonomous Maintenance group set a new goal for themselves: reduce the administrative burden in production. They set-up a brown paper in a room with all the different check lists and forms operators need to fill in during their shifts at different workstations, which sometimes also need to be digitized as well. The results from our time studies earlier this year showed the problem with the checklists and forms is more than the time it takes to fill them all, the problem also lies in variation. There are multiple variations of forms for different product families, variable intervals in which checks need to be done with variable instruments at variable locations and of course, the sample size also varies. Because variation (Mura) causes of more types waste (see Toyota 3M model) than the mentioned employee morale, it will be our task as a Lean team to find ways to reduce this variation. Improvements could be:

- Use standard formats/lay-out for all forms to make it easier for operators to fill in the forms

- Standardize the forms in a way that they can capture the results of 24 hours per piece of paper, to reduce the pile of paper on each desk and printing jobs.

- Integrate the forms used to perform the task in the steering and accountability meeting to eliminate the need for even more lists and print outs.

Continue to: